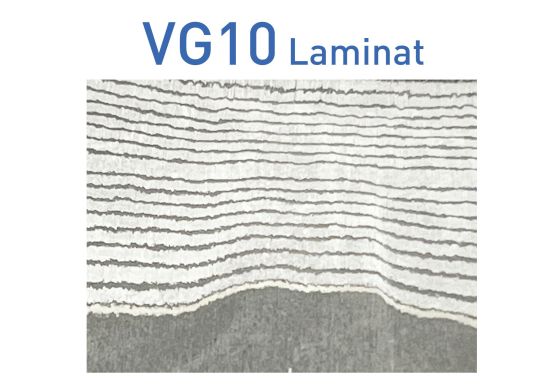

The structure of the finished laminate steel corresponds to the structure of classic damascus after the initial welding in the fire. The alloy components of the VG10 cutting layer correspond to steel with material number 1.4528, while the stainless steel side layers do not change their properties such as hardness and elasticity by heat treatment.

This is not an Alliexpress product, but a genuine TAKEFU product!!!

This steel is vacuum hardened with freezing to a hardness of approximately 61 HRC! Use our hardening services here Blade hardening - material purchased from us (including damascus blades)

Due to the central cutting layer, VG10 laminate is only suitable for double-sided ground blades, as in the case of wedge grinding the cutting edge is not in the centre of the material and in the case of highly asymmetrical grinding the side layers are either partially or completely removed. Also in asymmetric grinding, the blade position may not be on the VG-10 layer. It should also be noted that the view of the layer pattern can be very well controlled and emphasized by the type of grinding. However, possible grinding errors and inaccurate work can be easily detected by parallel layers.

Production method: fusion metallurgy of VG10 steel, side layers fusion metallurgy, layers welded together.

Areas of application: knife blades, jewellery

Properties in working condition: VG10 hardenable up to 60 HRC for knife blades, rustproof, holds blade well, easy to clean.

Properties in shipped condition: soft annealed, hardness max. 95 HRB

Processing information: suitable for machine processing, suitable for hand processing, easy to etch

Application properties: good sharpening properties, good cutting properties, easy to clean, very good polishing properties

Tips: heat treatment should definitely be done by deep freezing to use the full performance range of the steel, grindable with water/oil stones, ceramic and diamond grinding wheels

Blade angle to a minimum of 25° (depending on remaining blade geometry and use/handling, see notes above)

Care: just rinse (with/without detergent) and dry, oil film not necessary, simple re-polishing to highlight the layer pattern (possible depending on etching depth)

Manufacturer recommended heat treatment:

Preheat to 850° for 30 minutes, then heat to 1060° with a maximum dwell time of 10 minutes. Quench in oil preheated to 50° and immediately sub-freezed to -80° with a 60 minute holding time. The tempering is carried out for a minimum of 120 minutes at a temperature of 150°. Steel hardened in this way has a hardness at the core of 61-62 HRC. The second component of the weldment is not changed by quenching and still has a hardness of about 14 HRC when measured

Čeština

Čeština