San Mai Triple Rough Steel from Takefu Special Steel Co. LTD. Japan, with Shiro2 carbon steel core, used by Japanese masters mainly for Japanese style kitchen knives.

Carbon steel core Shiro2 contains very little impurities and is easy to heat treat. It has good ductility, workability and forgeability. The addition of Cr (chromium) and Ni (nickel) ensures refinement of the grain microstructure. The spheroidization of cementite ensures higher strength after hardening and higher toughness, along with a reduction in the tendency to chip the edge.

Shiro2 steel contains very few impurities andis easy to heat treat. It has good ductility, workability and is easy to forge. The addition of Cr (chromium) and Ni (nickel) ensures refinement of the grain microstructure. Heat treatment of Shiro2 steel is relatively easy. Because it is not as sensitive to quenching temperature, the growth of larger martensite microstructures is unlikely, although the quenching temperature for austenite will be slightly higher than standard. This ensures high quality and consistent heat treatment. Due to the high toughness of Shiro2 material, it can be used at extremely high hardness, Hrc 63-64 for culinary knives and 60-61 Hrc for sport knives. The thinner material is ideal for culinary knives. The thicker material is well suited for striking tools such as axes.

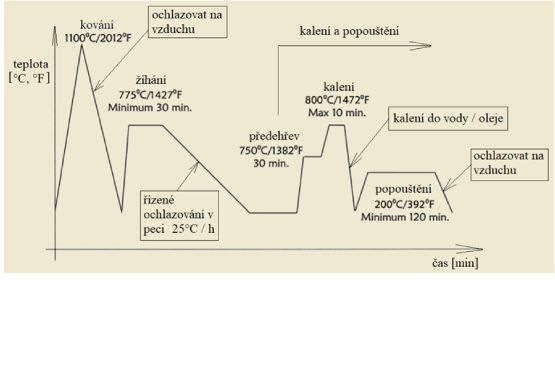

Furnace processing:

Forging at 1100 °C. Do not forge at temperatures below 1000 °C/1832 °F. Anneal after forging.

Annealing at 750-800°C. Cooling rate after annealing should not exceed 25°C/hr.

Hardening780-820°C. Quenching in oil (oil at 50°C) or water (water at 25°C)

Heat blade to 750°C, hold for 30 minutes, then raise temperature to 800°C and cool in oil. Hold temperature for a maximum of 10 minutes before quenching. Temper twice for two hours (200 °C ~ 64 Hrc) to achieve desired steel hardness.

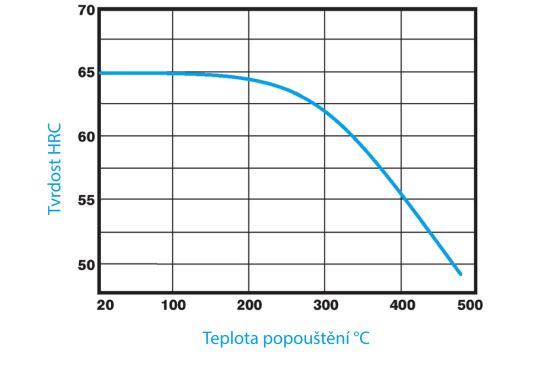

Dripping 150-250°C according to the required hardness according to the diagram

Čeština

Čeština